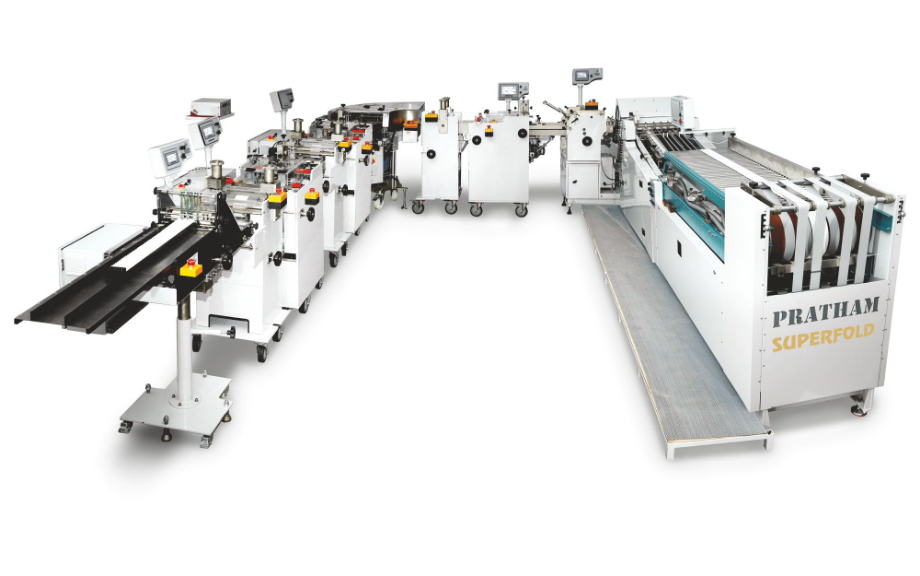

Superfold BFC-15/4 Pro right angle folding machine

2 – 8 buckle plates available.

Equipped with extra-long roller conveyor to feed 530 mm wide folded sheets to the folding unit smoothly. Patented design which facilitates the longer usage of the folding rollers. Folding rollers are made of steel and PU combination. The unique gear drive system allows to set folds up to higher thickness.

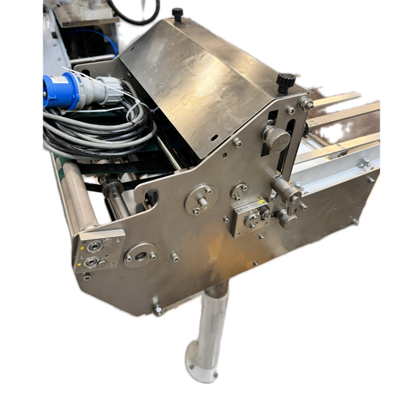

Parallel knife SK1

Parallel knife folding machine for thick fold with sheet running control and jam control Max width for Outsert Sample: 150 mm, Max height: 75 mm, Min width: 30 mm, Min Height: 30 mm, Max thickness for leaflet: 16 mm, Min thickness for leaflet: 2.5 mm Power specification: 230V (Single phase), 50hz, 0.5ph.Pneumatic Pressure: 4 to 6 Bar

Parallel knife SK1 - height adjustable

Height Adjustable Parallel knife folding machine for thick fold with sheet running control and jam control Max width for Outsert Sample: 150 mm, Max height: 75 mm, Min width: 30 mm, Min Height: 30 mm, Max thickness for leaflet: 16 mm, Min thickness for leaflet: 2.5 mm

Vision inspection Advance PSCPL Pharma Vision - OPF 35P

Camera based inspection system for Pharma code, Barcode and 1D, 2D & Pattern match Comprising of:a) 10.4” Industrial Panel PC b)2 smart cameras from Baumer (Germany) c) Console Unit d) Object sensor and assembly e) Necessary fixtures for camera mounting f) Cables and connectors g) Report generationh) 21 CFR i) Audit Report (Min. size 125 x 150 mm)

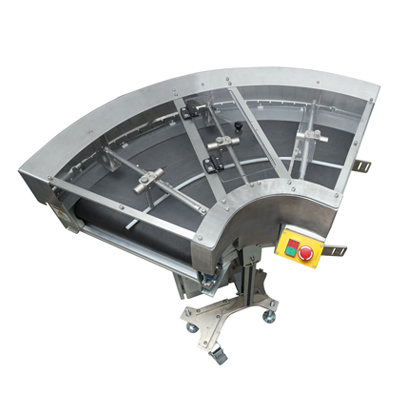

Vertical stacker for outserts HAVS

Max. Size: 150 X 75 mm (W x H) Min. Size: 28 X 28 mmStacking Folding Thickness: 2 to 16 mm Stacking Length: 1100 mmSpeed: 60 m/min (Depends on the Folding Format and paper quality) Voltage: 220 VAC, 50/60Hz Dimensions: 1700 x 470 x 1200 (L x W x H) Weight: 80 kg.Pneumatic Pressure: 4 to 6 Bar Batching and Counting

Novexx Taping machine

Rectangular Label: Max. Size: 170 X 80 mm (W x H) Min. Size: 38 X 38 mmThickness: 2 to 14 mmSpeed: 30 m/min (Depends on the Folding Format and paper quality) Round Label: Max. Size: 170 X 80 mm (W x H) Min. Size: 38 X 38 mmThickness: 2 to 8 mmSpeed: 30 m/min (Depends on the Folding Format and paper quality) CE MarkingVoltage: 230 VAC,50/60 HzDimensions: 2300 x 1450 x 900 (L x W x H) Weight: 250 kg.Pneumatic Pressure: 4 to 6 Bar Max. Label Size: 15 x 40 mm (W x L) Min. Label Size: 12 x 30 mm (W x L) Release Liner width: 15 to 18 mm

Novexx Double taping machine

Text to come…

Super print 150

Pratham’s in-line Outsert serialisation and inspection system are equipped with a jogger, Variable data printing, inspection of the printed codes and eject the misprint Ousert samples. The jogger is aligning samples in properly printable forms, where the misprint possibility will minimum. Inkjet printing head prints the 2D codes styles. A camera-based inspection system is used to check the printed code and eject the wrongly printed samples by air. Inline Outsert serialization and inspection system is simple to plug and start with easy to clean and maintain. below is the working specification of the machine to utilize in front of the outsert machines Specifications: 1) Max. Size: 150 (W) X 75 (H) mm 2) Min. Size: 28 (W) X 28(H) mm 3) Code Size: 8 to 12 mm 4) Speed: 30 m/ min. 5) Thickness: 3 to 18 mm 6) Max. code height 12 mm 7) Resolution: 600 DPI 8) Voltage: 220 VAC, Single Phase 9) IPC Panel to Handling Software

SUPERINSPECT 150

Pratham’s in-line Outsert inspection system is equipped with a jogger, camera- based inspection to folded outserts sample, software to verify the fold quality, and air ejection to eject the wrong outserts sample. The jogger is aligning samples properly. A camera-based inspection system is used to check the height, width, thickness, and accuracy of the folded samples. The software verifies the accuracy of the folded samples. The faulty sample gets ejected by air. Below is the working specification of the machine to utilize in front of the outserts machine Specifications:1)Max. Size: 150 (W) X 90 (H) mm2)Min. Size: 28 (W) X 28 (H) mm3)Speed: 30 m/ min. 4)Thickness: 3 to 16 mm5)IPC Panel to Handling Software

Super Tray Packer (STP 150)

Auto Tray Packing System is pick and place automation for outserts tray packing with tray loading, tray feeding and tray indexing mechanisms.

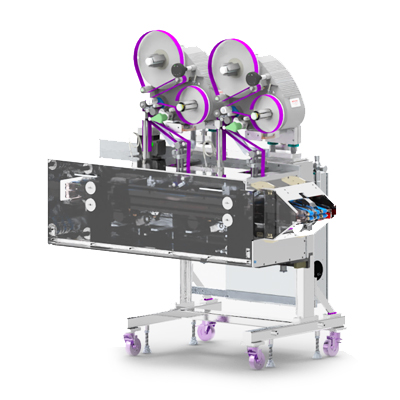

Super twin machine 2 - 4 heads available.

Lugged carrier type conveyor @3000mm long with 6-inch pitch. Inclined Friction Feeder. Booklet rejection system at end of lugged conveyor. Flat belt conveyor for manual collection of glued booklets @1200mm long. PLC HMI with Eldon Make electrical control panel. Hot melt Glue System with 2 nozzles. Bar code/Pharma code reader. Feasible product Size. Maximum Size: 100 mm X 100 mm. Minimum Size: 28 mm X 28 mm. Thickness: 2.5 mm to 15 mmCamera Code Scanner Feasibility. Code read by the top surface of the Outsert samples from 8 to 15 mm in dimensions. Barcode/ Pharma Code should be on white background printed black or blue colorSpeed.